Reliance Industries Constructs Road with Plastic Waste in Nagothane

Without any proper disposal, India has been struggling with the huge mound of plastic waste for the past few years now. Envisioning a potent solution to combat plastic pollution, Reliance Industries Ltd. (RIL) has constructed a 40-km pilot project of road network with 50 tonnes of plastic waste in Nagothane Township.

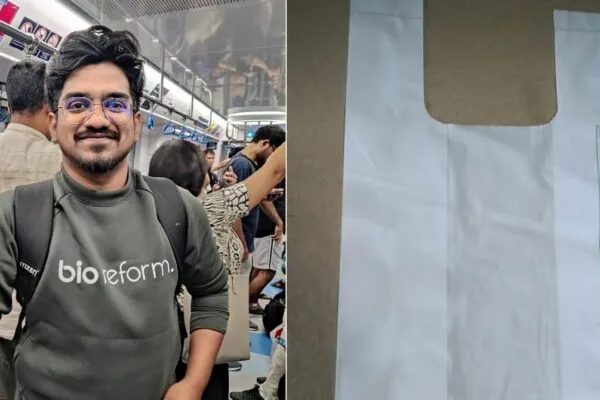

Image: Hindu Business Line

The plastics used in the road construction by RIL include single-use post-consumer plastics such as multi-layered films used for packaging of snacks, flimsy polyethylene plastic bags, flexible polyethylene packaging materials used by e-commerce companies, garbage bags, cling wraps, and other flexible plastic products collected from within the township and surrounding areas of Pen taluka.

RIL’s innovative team modified a hot-mix plant to automate and enhance the efficiency of the process of mixing single-use plastics with bitumen and gravel for constructing the roads.

The chief operating officer (COO), petrochemicals business, RIL, Vipul Shah said,

This is part of RIL’s endeavour to instill sustainability and circularity concepts in everything they do. The roads at Nagothane manufacturing division are a proof of concept that even end-of-life plastics can be utilised in a sustainable manner in creating meaningful and useful assets.

Mr. Shah commercially launched the Waste Plastic to Road initiative and declared phase one of the project as complete. He further added,

We will be happy to share our experience with governments and local bodies across the country to help increase the use of end-of-life plastics for such productive purposes. Apart from being beneficial to the environment, the use of plastics also enhances the quality of roads.

The construction of model roads started in May 2019 and was completed within two months. When the Raigad area witnessed heavy rains, the newly-built roads were submerged underwater for days, but there was no damage done to the roads. Fully-loaded trucks pass on these roads daily but the roads remain intact.

Also Read: Indian Engineer Makes Bricks from Plastic Waste for Sustainable Construction

In fact, the durability and strength of the roads have increased with the inclusion of plastics in the road mix. The superior bonding among aggregates, lower seepage of water, and lesser erosion are a few advantages of these roads. A road made with plastic – 3.5 meter wide and having a 5 cm topping – reduces the construction cost by Rs. 1 lakh as compared to a conventional road.

India produces plastic waste of over 25,940 tonnes every day. Waste management is one of the biggest challenges for the country. RIL is already processing 200 crores used PET bottles every year and has plans to double it in the next 15-18 months.

The company has plans to pitch the idea of using plastic waste in road construction to the National Highway Authority of India, municipal corporations, and other companies too.

Via: The Hindu